An extra month of capacity for free: Three Cs – Capacity

(Click here to watch on video rather than read!)

In the first two articles in this series, I went through the first two of the Three Cs that need to be in place so you can get out of the detail and start doing your real job. The three Cs are:

- Clarity

- Capability

- Capacity

(Click the links above to go the articles or click here to watch them all on video).

This article is about Capacity, which answers “How can I create more time for myself and my people which means I can do the important work that I’m actually paid for”.

Throughput and Shippable Units

Some terminology you need to know:

- Throughput – the number of shippable units that your area pumps out, or that you pump out every day, week, month, whatever.

- Shippable unit – a thing that can be given to someone else, whether it’s an end customer or a next step in the process.

- 8% – our key throughput number. By increasing capacity by 8%, you’ve given yourself an extra month of work without any increase in expenses. That’s an extra month of gross profit or an extra month of social value created without any extra effort. It’s worthwhile.

An increase in throughput without additional resources, without a drop in quality and no drop in sustainability means we have increased capacity. So that’s our goal.

There are two levels we work on here – the individual and the group or system level. The common link between the both of them is… focus. We all know “work smarter, not harder”. It should be “work focused, not less focused”. I’m going to show you how you do the focus.

Individual working

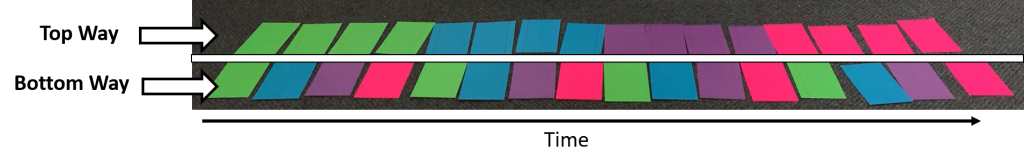

The diagram below lines up four projects, initiatives, whatever you want to call them. And each one of them takes four steps to get it done. You can see two ways that you can organise to get those steps done, with the card indicating a project stage, going from left-to-right. (I do this exercise in workshops all the time, it’s a great way to shift mindsets). The bottom way has doing a stage of each project, then shifting to another stage of another project, around and around… until done. The top way arranges so all four stages of a project are done consecutively until the project is finished (shipped).

Now, there’s a lot of pressure on us in our work to do it the bottom way. The reason is we believe that we won’t get pink done in time if we don’t get pink started as soon as possible. Just like this guy sang, if we wanna be startin’ something…

The other reason we work in the bottom fashion is customer pressure. Think about a builder. Once someone has paid, they want to see action. So, to demonstrate customer service, we get that foundation in now.

(I once ran this exercise with an actual building company. Smart, senior, dedicated people. Three groups studied the problem and not one arrived at the top way to organise projects. Not one! That’s how much a certain way of working gets ingrained!)

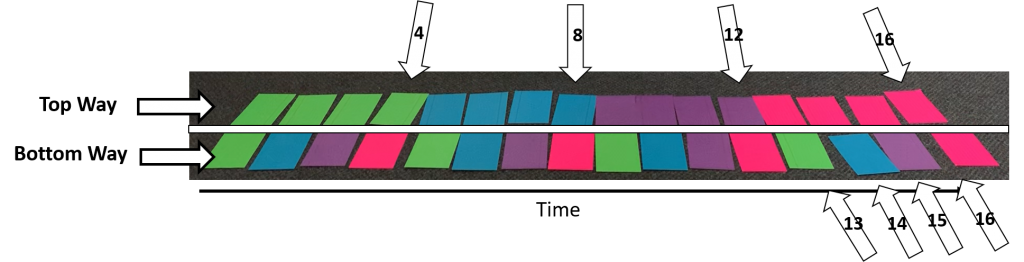

Completion times

Now look at the completion time for each of these ways of working. Remember, we must complete all four to get it done. The arrows in the diagram below indicate when each project is finished. Consider a business that invoices on project completion. One way provides cash to pay salaries and suppliers after four periods, the other not until 13 periods! And, when you add it all up, that’s 18 less periods of cash in hand by organising things the top way.

If you’re in the social sector, that’s a total of 18 more periods less value your clients have received.

For your own individual work, that’s 18 more periods that those you are producing the work for are denied being able to get on and do their next thing! And let’s not forget the benefits we get psychologically. Because whenever a project is complete, they stop bothering us! Which means we work faster.

Most of all….here’s the thing that we all miss. Pink is still shipped at the same time, regardless of which way we organise. Which means…there is no advantage to starting pink earlier. It’s done at the same moment. And more than that, thinking that pink really finishes at the same time under the bottom way of organising is an illusion. That way sees us switching from one task to another, we’re fielding customer complaints, we’re trying to get things sorted. So pink shifts to the right. As does the one before it. The whole thing extends to the right, because of all the bothering and switching.

And throughput, therefore capacity….drops.

Better, not perfect

Now, we can’t apply this principle perfectly, but I know if you look at the way you work, you can definitely apply these ideas to a fair degree more than you are already. If you’ve got three things that need to be done, line then up, then whichever one is due first, do that one first until it’s shipped. If they’re due at the same time, then do the most important one first until it’s shipped. And if you don’t think it’s possible to do all three, it wasn’t going to happen under the bottom way of organising anyway!!!

If you have to ship it out of your own personal work zone before completed, for example because you need advice from someone else, then you move onto the next project. As soon as that advice comes back though, you move back to the original one.

And of course you do the equivalent of putting the oven on to preheat first. Don’t be that rigid!

Remember, the last project finishes sooner if you focus on one thing at a time. This is the principle that significantly lifts personal capacity. Do it yourself, show it to every one of your people, or get touch with me to see if a short video seminar might work for your team.

Now…onto creating more group or system capacity.

How to increase the capacity of a work system

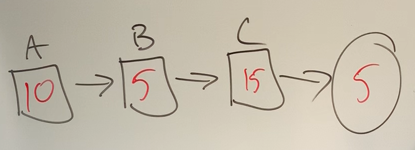

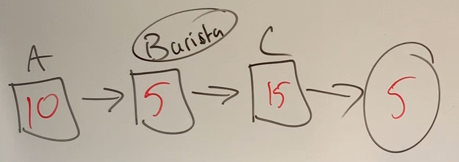

Let’s apply the principle of focus to creating increased capacity for a group or system. Remember increasing capacity means increasing throughput with the same resources. My long-term clients will recognise this diagram, one of my favourites:

Here we have a three-step process to getting something done. A, B and C. The number inside each box represents the throughput rate for each step in the process.

We’re going to say that A’s able to produce 10 per day, B can do five per day, and C can do 15 per day. The throughput, the shippable units this whole system can produce per day is…..five. It doesn’t take a lot of genius to see that the thing that sets the pace of the whole system is team/area/machine/person B. So, to increase the capacity of the whole system, we need B to be productive as possible.

Stop bothering the barista!

The first way we increase the capacity of B is we simply stop bothering them. If you’re the manager, protect person B. If you were running a café, you wouldn’t let a bunch of people come in and start yelling at the barista. Ask yourself why not? Because you intuitively know that B (for Barista) sets the pace of coffee production. Not the speed of taking orders, or the speed of passing the coffee to the customer.

A crucial aspect of stopping your Barista being bothered is to tell A to slow down. If A is external to your system, your job is to set something up so both;

- the Barista is not bothered, and;

- the customer experience is still maintained

The work has to somehow be routed into a waiting bay or if possible around B altogether. If you’re accountable for the work system, your job is to sort this out. And if you are the General Manager of people who are accountable for wok systems, your job is to help them to sort it out (there are various ways to do this, get in touch if you would like to know more).

You’ve been experiencing a real-life example of this, forced through necessity. Think about what’s happened during COVID-19, with people standing outside the bakery so you’ve only got two in there at a time. What’s been the staff experience (yes, I’ve asked them, organisational specialist at your service!) All those I’ve asked have said it’s better, because they know who to serve next and they’re able to get on and do it without feeling stressed about how many people to serve. This is causing quality to go up, which in turn sees less re-doing of orders or people returning to the shop. End result…throughput up!

(I know COVID-19 is a new situation for us. But the lesson to take is not “we need a global pandemic to increase throughput”. It’s “customers can be trained to increase throughput which ultimately helps them”)

The senior manager’s job

So your job, as a senior manager, is to set up the system to protect B. Do this and you’ll find that B’s productivity actually goes up. And if B’s productivity goes from five to six, the whole system goes from five to six. In my numbers here, that’s a 20% increase, but remember, all you need is an 8% increase to get yourself a free month!

Once you’ve got B as productive as possible (by them also doing the individual productivity things in the first part), and only once this has happened, you can then look into investing to further increase the productivity of B. Maybe shift resources, maybe invest in some technology. But don’t jump to investing. First, just stop bothering them, the difference will be huge.

End result – you doing more of your real job!

By you and your team grasping this simple and powerful concept, (it’s very unmarketably called ‘Theory Of Constraints’ in Production by Eliyahu Goldratt), you can significantly increase the throughput of the team.

And as we said at the start: An increase in throughput without additional resources, without a drop in quality and no drop in sustainability means we have increased capacity.

Increased capacity for your people means they can get on and do their work, which means you’ll be able to get on and do your work.

What to do now

Your next step is to get your own work lined up, show your people how to do it, then get started on identifying what throughput is and who your baristas are.

Thanks for reading, if you felt yourself thinking “hmmm” as you read this, please forward to someone else, or share. If you’d like to connect in other ways, you can find me on the usual socials.

And now….send me a message so I can point you toward some more resources that will help on this topic.